|

|

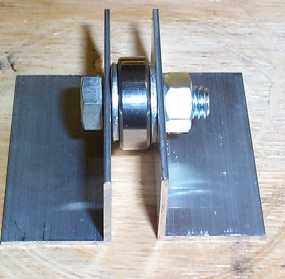

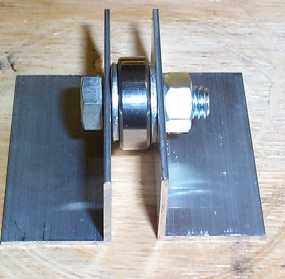

7/11 The drive system has been torn back apart again. It's time to make a few modifications to the system in hopes that it will run a bit smoother. The first mod is replacing the Teflon on Formica azimuth bearing surfaces with real ball bearings. Here's a few pictures showing how I'm approaching this. I had 8 in line skate bearings left over from the altitude bearings and decided to see if these will work. I was hoping to find a piece of U channel in which the bearings might fit, but didn't see anything like that in Home Depot. Instead, picked up a piece of 1/16" x 1" aluminum right angle and cut it down to 2" lengths. Drilled each piece out and fastened the bearings in place with 5/16th" bolts, washers, nuts and lock washers.

Here's the technique used to position the holes close to the same location on each piece of aluminum. A drill press would have made the job easier, but lacking that, I drilled a 5/16" hole through a piece of 3/4" plywood the right distance from the edge. Slid the aluminum under the edge and using 2 dry wall screws held the plywood tightly to the workbench. Then it was just a matter of running the drill down the hole and everything came out pretty close.

|

|

A completed bearing assembly is shown on the right. My only concern is that the 1/16" thick aluminum might be a bit thin for supporting the scope, but nothing seems to flex when I press down on a bearing with my whole weight behind it. The 3 bearings should each have to support approximately 35 pounds of telescope, so they should work.

In order to keep everything at the same height as the original Teflon, it was necessary to mount the bearings atop a 1/4" plate of aluminum. This was made from a piece of 1/8" thick flat stock I had used for the motor mounts. Here's a shot of the final product mounted on the ground board.

I discovered the large, flat piece of steel I bought for the original bearings to run against has already started to rust just sitting in the basement. Next project will be to pick up a thin piece of aluminum plate or galvanized steel to mount on the bottom of the rocker box. Also picked up a 3 foot long roll of cork and rubber gasket material. It's much easier to work with than the foam rubber, but not sure if it will provide sufficient sound dampening qualities. Hope to reach the point where I can remount the motors by the weekend. 5 seconds with power applied and the motors stepping will give a quick indication if the gasket material works or not.